How to Make a Perfect Rabbet Joint for Your Woodworking Project

Are you looking for the perfect way to complete your woodworking project? Look no further! I have the solution for you: a rabbet joint. There’s nothing quite like the perfect rabbet joint to give your project that perfect finishing touch.

So, let’s get started! Let’s learn how to make a perfect rabbet joint for your woodworking project.

First off, you’re going to need a few tools. For example, you will need a rabbeting plane, chisel, saw, square, marking gauge, and a hammer.

Now that you have all the tools, let’s go ahead and get started. The first step to make a perfect rabbet joint is to measure and mark the board. Using a square, transfer the mark to your board.

The next step is to make a groove. To make a groove, you need to create a beveled corner at a 90 degree angle at the end of your board. With a rabbeting plane or chisel, make a groove at the joint.

After that, you need to clip the corner. Using your square, line up the corner to the side of your board. With a saw, remove the excess wood. Make sure you measure carefully and remove as much excess wood as possible.

Now, it’s time to make a stopped rabbet. With a marking gauge, make a few lines along the inside edge of the corner. Make sure to use a saw and chisel and be sure to go lightly.

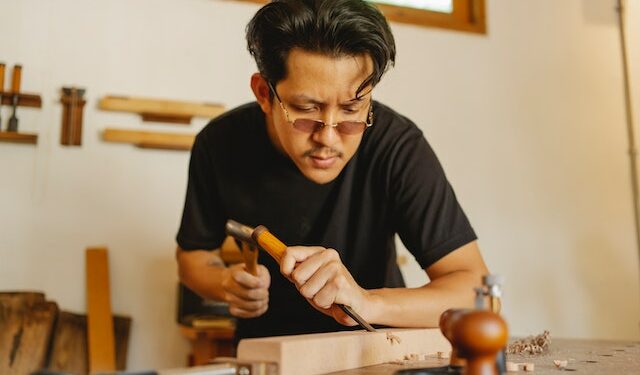

Finally, you’re ready to finish up the edge. Use a chisel and hammer to refine the edge and smooth the corner.

So, there you have it—the perfect rabbet joint in five easy steps! With these tips and tricks, you’ll be sure to create the perfect rabbet joint every time. Now, who’s ready to show off their woodworking skills?

Important Tools Required

Are you ready to take your woodworking skills to the next level? Making a perfect rabbet joint is the ultimate challenge, and you’re about to face it.

First things first, let’s go over the important tools required for making a perfect rabbet joint. You’ll need a hammer, a saw, a chisel, a couple of clamps, and of course a ruler.

Now, this is the part that could save your woodworking project from total disaster. Many people like to pretend they know how to handle the hammer and saw, but let me be honest with you—more often than not, they don’t. That’s why I highly recommend you practice on a scrap piece of wood first. Not only will this allow you to get a better idea on how to use the tools properly, but it will also keep the hammer from turning your piece of wood into kindling.

Speaking of hammers, make sure you have one that isn’t too light or too heavy. You’ll also need a saw that is designed for woodworking, not a cheap one that you might find in the local dollar store. Finally, a chisel is a must. Not only is it essential for shaping and smoothing out the rabbet joint, but it also makes it easier to fix any mistakes you may make along the way.

Now that you’ve gotten your tools squared away, it’s time to move on to the step-by-step instructions to make a perfect rabbet joint. But before you do that, take some time to make sure all your tools are in working order and ready to go. Making a perfectly fitting rabbet joint is a demanding task, and it’s better to be prepared than to have to rush out to buy more tools halfway through the project.

By following these guidelines, you’ll be able to make a perfect rabbet join for your woodworking project every time! So go ahead, get those tools out and let’s get started!

Step-By-Step Instructions

Welcome to the world of rabbeting! Rabbeting is one of the most important steps in your woodworking project. Today, we’re going to talk about how to make a perfect rabbet joint for your woodworking project.

I’m sure you know the saying: “measure twice, cut once.” Well, no truer words were ever spoken when it comes to making a rabbet joint! Before we get into the step-by-step instructions, take a minute to make sure that you have all the important tools and safety equipment required to make your joint perfect.

Step 1: Measure and mark the board. This part can be a little tricky, so take your time and be sure to measure your board twice if you need to! Keep in mind that the depth of the rabbet joint should be twice as deep as the width of the board — this will ensure a proper and secure fit. Once you have the board measured and marked, you’re ready to move on to the next step.

Step 2: Make a groove. This step requires a router and bit. Set your router up on a flat, stable surface and slowly guide the bit along the marked lines. You should move the bit back and forth a few times to ensure a smooth and even groove. Take your time with this step, as a poorly centered groove can lead to misalignment when assembling your project.

Step 3: Clip the corner. This is an important step in creating a perfect rabbet joint. Using a chisel and a hammer, carefully chip away any sharp corners on the rabbet joint. Make sure you do this on both sides of the joint.

Step 4: Make a stopped rabbet. To make a stopped rabbet joint, you’ll need to use a marking gauge and a small saw. Line up the marking gauge with the depth mark you made in Step 1 and use it to draw a small saw blade. Follow the line you drew with the saw and make sure you cut from both sides of the rabbet. This will help make the joint stronger and more secure when it’s finished.

Step 5: Finish up the edge. Now that you have the rabbet joint ready, all you have to do is to sand down the edges. This will help ensure that the joint fits snugly and also makes the joint look smooth and uniform.

And there you have it! Congratulations, you’ve made a perfect rabbet joint for your woodworking project! Now that you’ve learned the basics of making a rabbet joint, stay tuned for some tips and tricks on how to get the most out of your rabbeting experience!

Tips and Trick

Welcome to the fun part: tips and tricks! I don’t know about you, but I love tips and tricks when it comes to tackling a project. Here I’m gonna let you in on a few of my own personal tips and tricks that I’ve picked up throughout my many years of making rabbet joints.

First off, when it comes to making rabbet joints in a hurry, I find that using pre-cut grooves is the best way to go. Pre-cut grooves allow you to quickly and easily set up the rabbet joint without worrying about precisely measuring and marking the pieces. Of course, this doesn’t mean that you can’t measure it, but it does make it much easier and faster.

Second, I find that if I have multiple rabbet joints to make, it’s best to use a jig to make them all quickly. Using a jig allows you to precisely place each rabbet joint in the same spot each time, making the process much faster. Plus, jigs can help provide extra support when clamping, which helps make sure the joint is strong and secure.

Finally, I would also suggest using wood glue before clamping. I find that using wood glue before clamping helps ensure that the joint is extra secure and also helps further reduce any play in the joint. Plus, it’s always best to use glue whenever possible to ensure a strong, long-lasting joint.

So remember, these are just a few of my own tips and tricks that I’ve picked up throughout my many years of making rabbet joints. I hope these help you get the perfect rabbet joint for your next project and make your woodworking experience just a bit easier.