How To Choose The Right Saw Blade For Your Project

Choosing the right saw blade for your woodworking project can make a huge difference in the quality of your cuts and the overall success of your project. With so many different types of saw blades available, it can be overwhelming to choose the right one.

In this article, we’ll provide you with valuable tips and advice on how to choose the right saw blade for your project, taking into consideration the type of saw you’re using, the material you’re cutting, and the desired outcome. With this information, you’ll be able to make an informed decision and achieve accurate, clean cuts every time.

Getting Started

Yo, Howdy, and Welcome to my guide on choosing the right Saw blade for your project. I’m an expert on saws and saw blades – because I use ’em every day in my construction job.

Now, unless you’re a complete newb, you probably already know how important it is to have the right saw blade for your project. Sure, you could DIY it with any old blade you have lying around – and you can probably still get the job done. But you’re not going to get optimal results. Plus, you might end up damaging the blade, or worse yet, damaging your project.

So today, I’m going to show you the ins and outs of saw blades and how to pick the right one for the job. I won’t just be giving you a bunch of technical jargon, I’m going to give you tips and tricks you can use to make sure you get the best results. Let’s get started, shall we?

First up, how a saw blade works. Saw blades might look pretty simple, but there’s actually a lot of science behind how they work. A saw blade is made of a thin sheet of metal, with teeth along one edge. This sheet is then mounted onto a saw, like a table saw or a circular saw. When the saw is running, the blade vibrates, and that’s what makes it cut. The vibration allows the teeth to make small chips out of whatever material you’re cutting.

The type of the saw blade you use is going to depend on the type of project you’re doing. Blades come in a variety of shapes and sizes, and each one is designed for a specific purpose. There are blades for cutting wood, metal, plastic, and other materials. So, depending on what you’re working on, you’ll need to choose the right blade for the job.

For example, if you’re cutting wood, you’ll need a fine-tooth blade. That will give you a smooth and clean finish. But if you’re cutting metal, you’ll need a coarse-toothed blade with a larger tooth count. That will help it move through the metal more quickly.

And of course, now that you know the basics, it’s time to choose the right blade for your project. That’s just what we’ll be looking at next. So keep reading, and I’ll show you how!

How a Saw Blade Works

Ah, the saw blade. It’s like the heart of your project; without it, you won’t get very far! But what exactly is a saw blade, and how does it work?

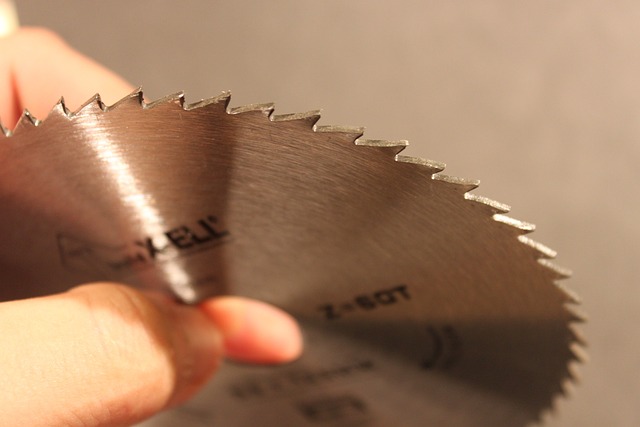

Well, a saw blade is kind of like a circular-shaped propeller blade, if you will, made out of metal with sharp cutting teeth along the edge. Depending on your project and type of saw, the saw blade is what attaches to the saw’s electric motor and spins around so that you can saw through wood, plastic, metal, and more.

When you turn on the saw, the electric motor turns the blade at speed that quickly saws through whatever material you’re working with. The teeth on the blade are what make this happen: they’re the part that actually make contact with the material and cut through it.

Now, the type of teeth that on your saw blade is really important. Depending on the material and the type of cut you’re doing, there are different types of teeth that are designed to make the project easier and give you the best-looking results.

For instance, if you’re cutting wood, a saw blade with more carbide teeth will make for a smoother, cleaner cut. But if you’re working with metal or plastic, a fine tooth blade with fewer teeth will work better.

And speaking of the teeth, you’ll also want to pay attention to the size of the teeth, and the spacing between the teeth. The smaller the teeth, and the closer they are together, the smoother the cut will be. Similarly, the larger the teeth and the further they’re spaced apart, the rougher and slower the cut will be.

So before you start your project, think about what type of material you’re working with, and then make sure you’ve got the right type of saw blade with the right shape and size of teeth to make your project a success.

Types of Saw Blades

Well, hello there! The first thing you gotta know about saw blades is that there are many different types of them! Confused? We don’t blame ya! Let’s break it down – saw blades come in many shapes and sizes, and they all have different uses. Let’s take a look at the most common types:

Circular Saw Blades: The most basic and commonly used blade out there. It has evenly spaced teeth and is designed for general cutting of materials like wood, plastic, and metal. They come in many sizes and can be used with handheld and table saws.

Miter Saw Blades: Designed specifically for making angled and miter cuts, these blades have teeth with alternating curved teeth that help make precise cuts.

Table Saw Blades: Used primarily for making rip cuts (lengthwise down the board), these blades have a flat top and deep, sharp gullets and are used in combination with a miter gauge and fence.

Jig Saw Blades: jig saw blades come in many different shapes and profiles – from straight, to curved and irregular. They are good for making precision cuts in wood and metal, and can be used with a handheld or a jig saw.

Hole Saw Blades: These blades come in different diameters for making circular or odd shaped holes in wood, metal, or plastic.

Band Saw Blades: Band saw blades are typically continuous loops of metal with evenly spaced teeth along one edge. The range of sizes and tooth configurations allow them to be used in resawing, making curved cuts, and cutting irregular and irregular shapes.

Now you know the different types of saw blades. So, next time you go shopping, you’ll know just what kind of blade you need for your project!

Choosing the Right Blade

Welcome to the exciting world of saw blades! Before you get started, you’ll want to make sure you have the right saw blade for your project. Trust me, once you figure this part out, sawing will be a breeze.

Let’s break it down. Different types of projects require different types of saw blades. If you’re cutting through soft materials like plastic, you’ll need a finer blade with more teeth. Conversely, if you’re cutting through tough materials like concrete, you’ll need a wider blade with fewer teeth.

Once you have the type of saw blade you need figured out, you’ll want to think about size. There are so many different sizes to choose from, but the size of your saw blade is directly related to the size of your project. In other words, the larger the project, the larger the saw blade you’ll need.

Once you’ve determined the size, you’ll want to think about tooth count. This determines the speed and smoothness of your cut. Fewer teeth will give you a quicker cut, but the edges might not be as smooth. More teeth will give you a slower cut, but provide a smoother edge.

Next, you’ll need to think about the material of your saw blade. Most blades are made from steel or carbide. Steel blades are good for general use, while carbide blades are best for tougher materials.

Finally, you’ll want to consider the blade’s kerf, plate thickness, and hook angle. Kerf is the width of your cut, plate thickness is the thickness of the blade, and hook angle relates to the angle of the teeth.

Now that you know all the details, you’re ready to choose the right saw blade for your project! Good luck and have fun!

Types of Projects

Wassup! I’m here writing about the types of projects you might use a saw blade for. Yes, I’m talking about a tool, a saw blade. Now why in the world would this dude be talking about saw blades, you might be wondering?

Well, a saw blade is an important tool and I want to make sure that you – yes, my reader, get the one best suited for the project you’ve got at hand. Because, if you don’t, and you go cutting stuff with the wrong diddly, you could end up with a dastardly mess on your hands – and ain’t nobody got time for that

But fear not, Groovy Beans! That’s why I’m here. I’m going to get you squared away, properly informed and savvy enough to pick the right saw blade. Now, before I get into the nitty gritty of this thing you should know that between carpentry, basic DIY and metalworking, there is a wide range of projects that require the use of a saw blade.

Let’s start with carpentry projects. If you’re going to be making something out of wood – and we’re not just talking tables here, crafting furniture, birdhouses, bookcases, picture frames and lots of crafty projects like that – then you’re gonna wanna get a crosscut saw blade. Why? Well, it’s simple. This type of blade cuts across the wood grain safely and cleanly, making sure whatever project you’re making comes out with subtle attractive lines.

Got some metalworking projects planned? Then you’re looking for a harder blade with lots of small teeth, the smaller the better. You’ll want something that will cut through thicker materials, such as steel and metals that have a higher melting point, like titanium, copper and aluminum.

If you’ve got some simple projects in mind, or you’re just starting out, then a basic DIY saw blade should do the trick. This is a versatile blade for general tasks such as making wooden boxes, cutting through thin planks, or plain carpentry tasks like making shelves or shelves and drawers.

No matter what project you’ve got in mind, make sure you get the right saw blade. otherwise you’ll end up with a dastardly mess. Now, get out there and start sawing!

Different Blade Sizes

Aww yeah – now we’re getting into the real basics of saw blade selection. Picking the right blade size for your project can be intimidating – let’s break it down and understand why size matters.

First things first: what’s a saw blade size? That depends on two things – the diameter of the blade and the number of teeth it has. It doesn’t really matter what type of saw you have, the only difference is the size of the arbor hole, which is the hole in the middle of the blade that fits onto the saw’s drive shaft.

Let’s start with blade diameter – this dictates how wide a cut the blade can make. Most blades range between 4-10 inches in diameter, though you can find larger ones. The larger the blade, the bigger the cut it will make. This is important if you’re looking to make really wide cuts in things like plywood.

Then there’s the number of teeth. This is a bit more complicated, since there are a variety of styles of blades with different teeth count. Generally speaking, the more teeth a blade has, the finer the cut will be. A blade with fewer teeth will create a rougher cut, so it’s best saved for tougher materials like metal. This is why a plywood blade usually has more teeth than a metal cutting blade.

Also, depending on the type of project, you may need to consider the kerf width of the blade – the kerf is the width of the cut produced by the blade. If you’re after a really precise cut then you’ll want to use a blade with a narrower kerf, as that will reduce the amount of material that has to be removed.

The bottom line is, size really does matter when it comes to saw blades. Different blade sizes and tooth counts can make a huge difference in the final product. Take your time and do your research – it’ll pay off in spades when you’re sawing away on your project.

Blade Tooth Count

Hey everyone! It’s me here again and in this section, I’m gonna be talking about blade tooth count! Before that, it is important to caution everyone reading this to take extra caution when dealing with saw blades. Safety should always come first, be sure to keep that in mind!

Now, I know that most of the time when it comes to saw blades, you may have heard someone saying that more teeth are better. But it is not always true. It all depends on what type of project you are working on.

Let’s start with the basics: the blade tooth count refers to the number of teeth in a blade on a saw or router bit. If you are working on very hard materials or thick wood, then a blade with more teeth would be the best option. This is because the blade can cut the materials slower but more accurately. On the other hand, if you are working on softer materials or thin wood, then you would want a blade with fewer teeth. This is because the fewer teeth can cut faster and make rougher cuts that are not as detailed as blades with more teeth.

Now let’s talk about kerf, which is the thickness of each individual blade tooth. This is important because it affects the amount of material you will remove with each pass of your saw. Blades with more teeth have thinner kerfs, which can be beneficial for making smaller and more precise cuts. Alternatively, fewer teeth with thicker kerfs are better for quickly cutting through large amounts of material.

But that’s all I have for blade tooth count, cause with the right blade, your projects will be crazy tight and look smooth as heck! Now, some folks might say that I should talk about hook angles as well, but that’ll be for another section of this article. Until then, be sure to stay safe and watch out for those blades!

Choosing the Blade Material

Ah yes, now comes the moment of truth! Choosing the right blade material, to make sure you get the right cut for your project. No matter what type of saw you’re using, the material of the blade is an essential element for all projects. Here’s a lowdown on the different types of blades and what kind of projects they’re suitable for.

First up, there’s the high-speed steel blade. This type of blade is typically the best choice for working with metal, whether it be copper, bronze or stainless steel. The high-speed steel blade stays sharper longer than other blades, so you can make several cuts without having to replace the blade. Just make sure that when you’re working with metal, you don’t forget to keep your blade and work surface well lubricated so that you can get the best results.

When you’re working with wood, then you’ll want to choose a carbide blade, as it can easily cut through softer wood and can handle hard wood as well. The carbide blade is sharp, durable, and lasts a long time, even with repeated use. Just like metal, one of the most important things to remember when working with wood is to keep your blade lubricated as this will ensure you get the best results.

For more delicate projects, like cutting veneers and thin laminate, then you should use an ultra-thin kerf blade. This blade is the thinnest blade on the market and can make incredibly clean cuts with minimal wastage. If you’re working with veneers, then this is the ideal choice for getting the perfect cut.

Finally, there’s the diamond blades, which you can use for quarry stones or tile cutting. Diamond blades are made of tiny diamonds, which are the most durable type of blade material available and also last the longest. However, due to the nature of diamond blades, they can be very pricey.

Weighing everything up, there’s no one-size-fits-all when it comes to saw blades and choosing the right material. There are many factors you need to take into account such as the type of project you’re working on, the type of material you’ll be cutting, and even the types of cuts you’ll be making. So do your research and choose the right saw blade material for each project to get the best results possible.

Kerf, Plate Thickness and Hook Angle

If you’re a woodworker, it’s likely you know what the phrase “kerf” means. The word comes from the French verb “couper,” which means “to cut.” Basically, the kerf is the width of the cut a saw blade will make – and it makes perfect sense that the wider a saw blade, the wider the kerf will be.

Saw blades come in different thicknesses, too. Plate thickness measures the depth of the blade, in thousandths of an inch. And for blade tooth counts and other considerations, you’ll want to consider a blade thickness that matches the job you’re doing.

That leads us to the last term you need to know about. It’s the “hook angle” and it’s a measure of how “hooked” the teeth of the saw blade are. A shallower hooked angle will make a less aggressive (read: smoother) cut, while a greater angle makes a more aggressive cut.

So there you have it! Those are the 3 key components to consider when choosing the right saw blade for your project. Keep in mind that having the right tool will help make your job easier, and the more familiar you are with the lingo, the better off you’ll be!

And remember, if you come across a term you’re not familiar with just give ol’ me a shout – I’ll be here to help guide you through the world of saw blades. Happy cutting!

Caring for Your Blades

When sawing your way to success, keeping your saw blades in tip-top shape is a must! But with all the options and decisions that go into selecting the perfect saw blade for your project, it can be easy to forget about properly caring for it. Well, today’s the day to turn that all around. Here’s what you need to know about the right way to care for your blades.

First up, sharpening your blades. It can be tempting to just go ahead and buy a new blade if your old one gets dull, but why waste the money when you can sharpen it yourself? The best thing to do is to use a dull blade against a grindstone until it’s back to its shiny self. Just remember to check the grindstone often and replace it when it gets too worn down.

Next, you gotta store those blades correctly. It may seem like you can just rush for your next project and let the blades hang about carelessly, but that won’t make your blades last long. As a rule of thumb, put your blades in a dry spot where they won’t be exposed to extreme temperatures or moisture. It’s also a great idea to use a toolbox with some foam padding to keep those blades nice and safe.

Finally, it’s important to always wear the right protection when sawing. This means keeping your eyes and hands covered with protective gear when sawing and also making sure that all your blades are in good condition. If ever you start to feel uncomfortable while sawing, go ahead and take a break until you’ve got the safety issue shored up.

Caring for your saw blades doesn’t have to be too tricky. Keep it simple, jazzy, stay safe and your blades should serve you well. It’s a win-win. Now you can make those ambitious woodwork projects without ever having to replace your saw blades! So, don’t be afraid to take that extra step and show some love for your beloved saw blades. Trust me, your wallet will thank you in the end!

Sharpening Your Blades

Man, I’m so excited to be talking about sharpening saw blades today. You never realize how important it is until you’re in the middle of a project and your blade’s going dull, making it that much harder to get the job done.

Sharpening saw blades is no joke. You gotta know what you’re doing. But once you got the hang of it, you’ll be sharpening blades like you were made for it.

First off, you need to make sure you’re using the right sharpening tool. The best way to do this is to check the manual that came with your blade. Most blades come with instructions on what type of sharpening tool is best for it. There are also websites that have that info if you can’t find your manual.

Next, you wanna set up the sharpening jig. This is a tool that holds the saw blade in place while you sharpen it. It also allows you to sharpen both sides of the blade at the same time. After that, you’re ready to get to work!

Then you want to apply light, even pressure while you sharpen. You don’t wanna press too hard and risk damaging the blade, so it’s important to be careful. Don’t be afraid to take your time and make sure you’re doing it right.

Once you’ve gone over the blade a few times, it’s time to admire your work! Give it a good look to make sure you achieved the desired result and that there are no burrs or rough edges.

So go ahead, get out there and get that blade sharpened. It’s good to have a sharp blade handy, so you’re always ready to tackle your next project. Peace out!

Safely Storing Your Blades

Safely storing and looking after your saw blades is just as important, if not more so, than choosing the best saw blade for your project in the first place. After all, a saw blade that isn’t looked after properly may become less effective due to wear and tear; and, if you don’t store it safely, it can become hazardous to the user.

That being said, it’s not too hard to keep your blade in good condition. The first step is to store it somewhere where it is unlikely to become damaged. It is best to put it in its original packaging, such as a cardboard box, or some kind of plastic container, and store it in a dry place away from direct sunlight or sources of moisture.

If the saw blade is still attached to the saw, make sure you loosen the blade tension before you store it. Not only will this prolong the life of the blade, but it will also make it easier to learn how to mount a blade when you’re ready to use it again.

It’s also a good idea to clean the blade before you store it, to remove any sawdust or other debris that can build up over time. A stiff brush and a soapy cloth should do the job.

If your saw has removable blades, it is best to store them separately in the order you will use them. That way, you won’t be rummaging around looking for the right blade when you need it. Giving each blade a label can also help with organisation.

Finally, it is wise to keep your blades away from small children and pets, in a place that is both secure and out of reach. Alternately, if you are concerned that they may be a potential hazard, you can get a secure storage box or cabinet.

In conclusion, safely storing and looking after your saw blade is essential if you want it to be in the best condition for when you need to use it. Investing in quality storage for your blades is an investment in quality workmanship – and that’s something every woodworker wants.

Using Protective Gear

Being safe is always the highest priority when using saw blades – so don’t forget to put on those safety goggles, folks! Whether you’re sawing wood, metal, plastic, or anything else, there’s always a risk for debris and debris can fly into your eyes if proper precautions aren’t taken.

Saw blades generate heat, which can mean burning your hand if not careful. Make sure you are wearing proper work gloves when using saw blades – not only will it help protect your hands from cuts and kicks back but will also protect against the heat generated from friction. Hand protection is key to both safety and efficiency!

Heavy duty protective footwear is also essential when using saw blades since they have sharp edges and the potential to kick back. Steel-toe boots are best if you are in a shop environment, or simply wear a thick durable shoe when cutting at home. For extra caution, install a guard on your saw blade that will contain any chips or drops when sawing wood.

It’s also wise to wear a dust mask when using saw blades. Sawdust can be extremely irritating to the nostrils and respiratory system, so wearing a dust mask prevents this from happening. Plus, the dust mask will help protect against any potential unpleasant odors while sawing to boot!

In conclusion, safety should always be your first priority when using saw blades – so make sure you’ve got on those work boots and protective gear! From noise protection to dust prevention, preparing yourself and your environment with the right gear will be sure to keep you safe, healthy, and successful in your project.

Conclusion

Well, I hope y’all put some of the things we learned here to good use.Now you should be able to choose the right saw blade for any project. Remember, the key to getting the right saw blade is to first understand how a saw blade works and the different types of blades available. Once you know the types of projects you’ll be using the saw blade for, you can start to narrow down the best size and features you’ll need to get the job done.

When it comes to caring for your saw blade, always make sure to sharpen it regularly and store it properly. It’s also important to protect yourself and wear the right protective gear when using a saw blade. Safety first, right!

Thanks for joining me for this guide to choosing the right saw blade for your project. Just remember, all the information and tips we went through here and you’ll be sure to make the right choice every time. All the best, and have fun sawing!